Learn more about the methods which are employed by IDP Lab

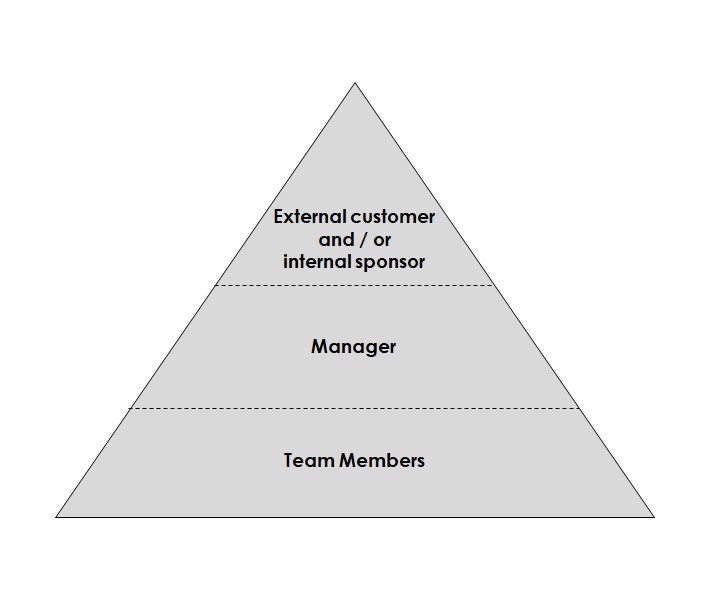

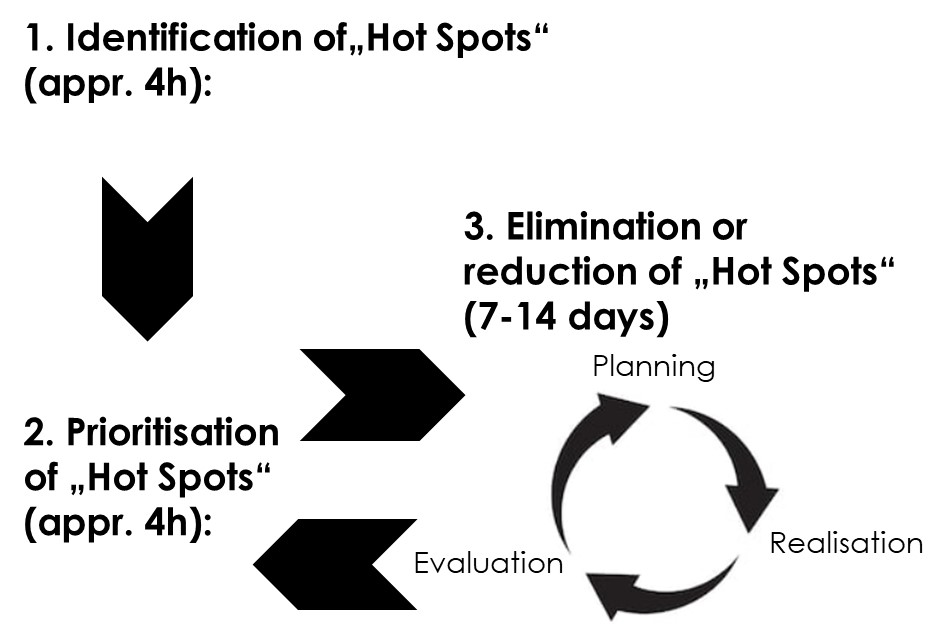

We usually start with a "Triple Decker Workshop" with an intended time frame of one day. Said workshop requires thress groups of participants: Custmer and / or Sponsor, Manager and Team Members. This workshop produceses three results:

For adressing the prioritised "Hot Spots" we usually plan a short cycle iteration of one to maximum two weeks. We follow the policy to run one "lean cycle" together and, after that, to hand over further improvement cycles, if necessary, to you. The improvement iterations are designed to generate one or more of the following results:

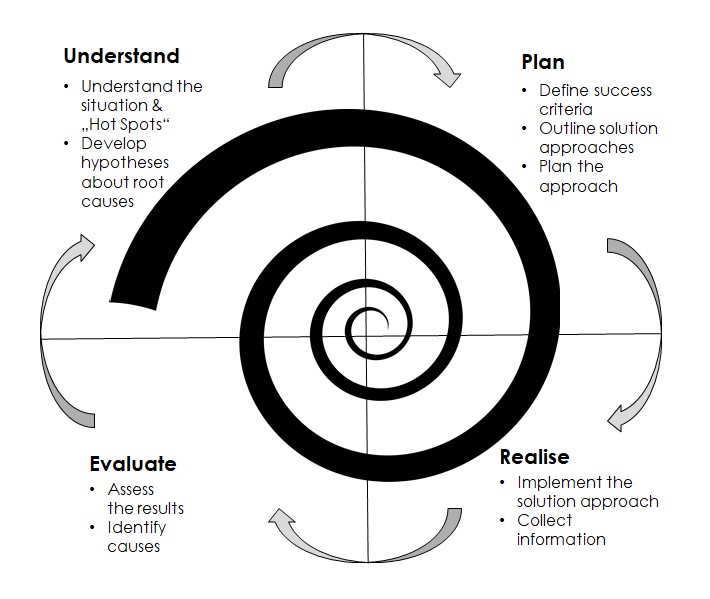

We support the improvement iterations by following a scientific "Action Research" approach in which....